Aerzen USA insights and guidance for blower, compressor and vacuum pump applications

Aerzen USA Named Best Places to Work in PA 2015

Tags: Aerzen USA

Aerzen USA has made a change in company's administrative structure. Pierre Noack has been President of Aerzen USA for over 30 years and the company has achieved growth and success. It is at this time that his services are required to support the development of Aerzen’s Worldwide Process Gas Division. He will be moving to Germany, near Aerzen, and will be working at the Aerzen headquarters. Additionally, he will remain on the Board of Directors of Aerzen USA.

Tags: Aerzen USA

Oil-free Air Conveying In Coffee Roasting Equipment

For transport of the coffee, Probat prefers the pneumatic conveyance. As the

conveying air is in direct contact with the product, it has to be absolutely oilfree. For production of the conveying air as negative pressure, Probat has used Aerzen units since 1996.

In September 2012, Probat opened a new Research and Technology Centre. There, the conveying air required in the roasting machines is generated by two Delta Blowers Generation 5 and one Delta Hybrid. Upon storage of the green coffee into silos with overpressure between 1,000 and 2,000 mbar, the Delta Blower is used, also during transport to the roasting machine with positive pressure.

The Delta Hybrid is responsible for transport of the particularly sensitively

roasted beans to the roasted coffeesilos and to bagging station with negative pressure as well as for transport to grinding plant with overpressure. The Delta Hybrid unit generates a negative pressure of 300 mbar on suction side as well as an overpressure of 600 mbar on discharge side. Therefore, a conventional blower unit could be replaced acc. to the principle “Two become

one”.

Again, two Delta Blowers transport the ground coffee to the ground coffee silos and to the packaging machines with negative pressure. As an alternative, however, the Delta Hybrids can also be used. The required differential pressure is decisive for the selection dependent on the piping length and the specific energy advantages of the Hybrid.

All Aerzen units are fully automatically integrated in the process of the roasting equipment and are switched via a superordinated intelligent SPS control depending on the program. The respective blower units are driven with a constant volume flow whereby the pressure is built up depending on conveying capacity and pipe length. Thanks to a bypass solution, Aerzen

had developed together with Probat, a part of the volume flow can be led back from discharge to suction side for the positive pressure units.

Tags: Aerzen, rotating equipment, rotary lobe blower, pneumatic conveying, Hybrid Blower, Coffee Conveying

Aerzen USA's Business Philosophy: People, Planet & Prosperity

Aerzen USA is well known for blowers, compressors and vacuum pumps. However the key to success is in the company's business philosophy featuring collaboration with customers and following a "Triple Bottom Line" mindset that includes People, Planet & Prosperity.

Aeration Blower Saves $44K Annually For Wastewater Treatment Plant

The segment from WaterOnline Radio features interviews with John Franz, wastewater treatment plant manager for the City of Anacortes, WA, as well as Kevin Grant, a regional sales manager for Aerzen USA.

Tags: Aerzen, positive displacement, rotating equipment, Aerzen USA, pd blower, rotary lobe blower, turbo blowers, blower sizing, wastwater, water treatment, WWTP, aeration

A Turbo Blower for the Base Load, PD Blower for the Peak Load

A biological municipal wastewater treatment plant with a considerably fluctuating discharge quantity can only perform its function with utmost energy efficiency and reliability if the process air consumption of the aeration basin can be adjusted continuously and is fully automated in order to deal with widely fluctuating load quantities. The example of the wastewater treatment plant shows how this is achieved with the use of a speed controlled Aerzen turbo blower.

Tags: Aerzen, positive displacement, rotating equipment, Aerzen USA, pd blower, turbo blowers, blower sizing, wastwater, water treatment, WWTP, aeration

More pressure for Aerzen Process Gas Compressors

Due to a new bearing and shaft design it is possible to increase the maximum admissible differential pressures to 25 bar in the process gas compressors VRa 236 H and VRa 336 H. Thus, with a multi-stage unit discharge pressures of up to 53 bar abs. can be reached.

Tags: Aerzen, compressors, screw compressor, oil-free screw process gas compressor, Aerzen USA

How To Choose The Right Blower For Wastewater Treatment (Podcast)

Three main blower technologies are condsidered for waste water treatment applications:

Tags: Aerzen, positive displacement, Aerzen USA, pd blower, rotary lobe blower, turbo blowers, blower sizing, wastwater, water treatment, WWTP, aeration

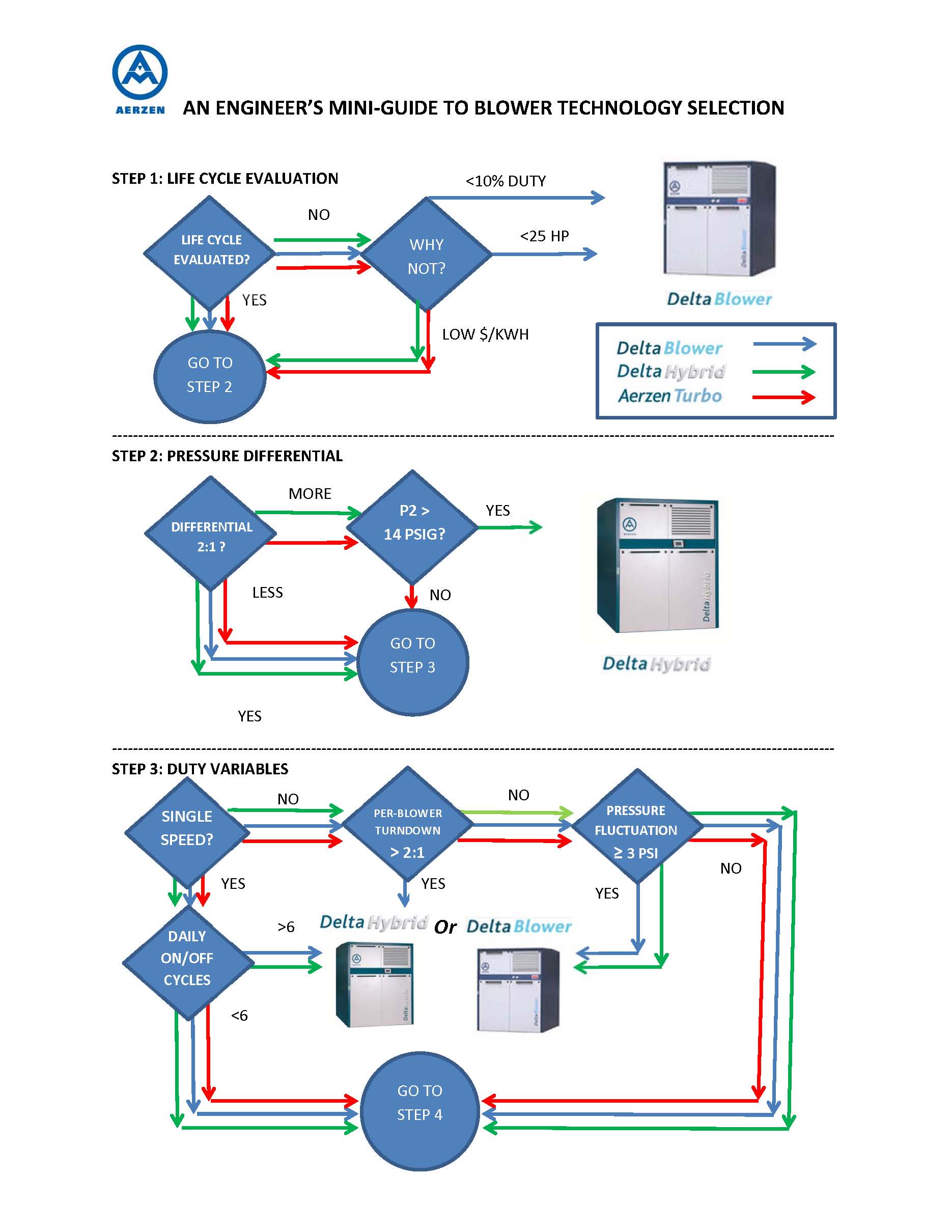

An Engineer's Mini-Guide To Blower Technology Selection

Turbo Blowers. Positive Displacement Blowers. Hybrid Rotary Lobe Blowers. Which one should you choose for your wastewater treatement application? How much energy can you really save? Who can you trust to give you an objective answer? The best place to start is by downloading the Engineer's Mini-Guide To Blower Technology Selection.

Tags: Aerzen, positive displacement, compressors, Aerzen USA, pd blower, rotary lobe blower, turbo blowers, blower sizing, wastwater, water treatment, WWTP

Real-time Condition Monitoring For Blowers And Compressors

The Aerzen iAir Remote Monitoring System (RMS) is a comprehensive monitor that can be attached to any blower or compressor to capture real-time activities and conditions. Based on industrial cellular technology, the RMS can function in any location with cellphone coverage for both indoor and outdoor applications. The system is easily installed and linked directly to your cell phone for up-to-the-minute condition reports and notifications. This allows for peace of mind and troubleshooting when you are not accessible to the equipment.

Tags: Aerzen, positive displacement, Aerzen USA, pd blower, rotary lobe blower, pneumatic conveying

Call to action will go here below

This is the content. This is demonstration text. Click 'edit' above to create your own content.