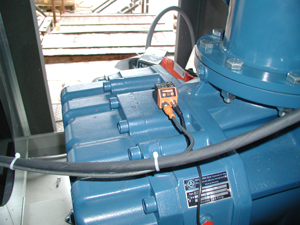

Trending is the key to success with precision maintenance. At Aerzen USA we make good use of state of the art condition monitoring devices that fit any budget. From low cost vibration sensor based switches to full blown online monitoring systems ranging from IFM Efector's VKS, Octavis and Multiplex devices we have the trending system that will fit anyone's budget.

Any of the devices will at least alarm the user of trouble and also at the same time provide the output of external trending. The more sophisticated Octavis and Multiplex units have their own built-in internal trending software, which is set up at the factory using our own expert information. It can eliminate any blowers and compressors from any existing regular vibration analysis routes as the units are constantly monitoring the equipment in real time and are set up with their own alarm and shut down levels. Customers with real critical pieces of equipment might even choose the Ethernet based connection that allows customer SCADA or DCS integration.

In any system that you choose, make sure that you do not implement without prior planning session as well as planning to review your results. Also, keep in mind that results are only as good as the accuracy of the information that goes into the monitoring equipment. Then always focus on trending and only fix what needs fixing. That is what I call Precision Maintenance. One reading alone may not mean anything; or would you only consult one doctor before you undergo open heart surgery because of a single high blood pressure reading?

Please drop me a note in case you have suggestions or questions.

Aerzen USA

Ralf Weiser

rweiser@aerzenusa.com