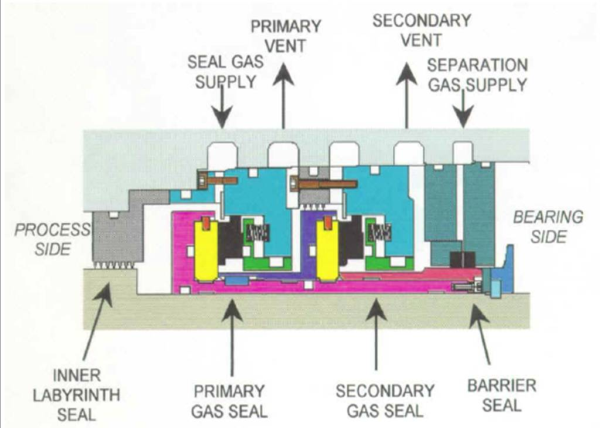

Oil-free compressors are most often used in process gas applications. Hazardous, poisonous or simply dangerous gases are usually being compressed and conveyed by our screw compressors. It is critical therefore, that such conveying media be sealed against leaks to the atmosphere or, in the case of gases incompatible with lubrication oils, against leaks into the compressor's lubrication system. Dry gas sealing systems are often applied for such tasks.

Aerzen USA insights and guidance for blower, compressor and vacuum pump applications

Oil-Free Screw Compressors – An introduction to Dry Gas Sealing Systems

Tags: Aerzen, positive displacement, rotating equipment, compressors, flare gas compression, screw compressor, oil-free screw process gas compressor, coke oven gas, lime-kiln gas, hydrogen, Aerzen USA, seal gas

Considerations when specifying and purchasing a screw compressor

1) Type of compressor: positive displacement or dynamic

Tags: Aerzen, positive displacement, rotating equipment, compressors, screw compressor, oil-free screw process gas compressor, pd blower, rotary lobe blower, turbo blowers, sliding vane compressor, oil-flooded screw compressor

Applying the proper flare gas compression technology

The refinery flare gas can be considered one of the most challenging, but it can be handled with the right compressor.

Tags: Aerzen, positive displacement, rotating equipment, flare gas compression, screw compressor, oil-free screw process gas compressor, coke oven gas, lime-kiln gas, hydrogen, sliding vane compressor, oil-flooded screw compressor, centrifical compressor, hydrocarbon combinations

Things to consider when making blower purchasing decisions

Performance - Only buy Aerzen's blower packages... just kidding, but there is a serious point here. Any manufacturer's claims of performance need to be verified to insure the correct amount of pressure will be generated for the application. Insist on knowing the performance and efficiencies (power requirements) of the complete blower package you buy not just the performance of the bare stage. An undersized drive motor will limit performance.

Tags: Aerzen, positive displacement, rotating equipment, pd blower, rotary lobe blower, turbo blowers, pneumatic conveying

Top questions to ask when buying a blower for a Pneumatic Conveying System

-

Is the blower sized for the correct amount of air? Too much air will lead to higher pressure drops and increased power consumption. Too little air will result in line plugging.

- Is the blower and motor sized with enough safety to overcome upset conditions?

- When comparing blowers from various manufacturers, did you look at:

- Reliability

- Efficiency

- Noise

- Maintenance requirements

- If you are conveying food products, you also want to make sure that no particles of the silencer absorption material and no lubrication oil can enter the compressed air stream and thus mix with the conveyed product.

Feel free to comment or contact me to discuss.

Karl Mueller - Industrial Specialist

Aerzen USA

(770) 951-7035

kmueller@aerzenusa.com

Tags: Aerzen, positive displacement, rotating equipment, rotary lobe blower, blower sizing, pneumatic conveying

Call to action will go here below

This is the content. This is demonstration text. Click 'edit' above to create your own content.