Oil analysis and vibration analysis make a great tag team when it comes to assessing rotating equipment condition. Even if oil analysis trending is carried out by itself it still can be a powerful tools assessing whether or not there may be trouble coming down the pike – rolling element bearings, gears and other key components leave key evidence of them failing behind in the lubricant. Depending on your plant size and usage of lubricant, quite a few lubricant suppliers also offer free oil analysis. While that seems great at the first glance, there are quite a few wrinkles that can lead straight to catastrophes that the analysis was supposed to help prevent. I will review a few issues and elaborate on what an analysis report should cover in the course of this blog.

Aerzen USA insights and guidance for blower, compressor and vacuum pump applications

PD Blower "Free" Oil Analysis - There Is Usually A Good Reason For It

Tags: Aerzen, positive displacement, rotating equipment, screw compressor, pd blower, rotary lobe blower, turbo blowers, WWTP, pneumatic conveying

Preventive Maintenance or Precision Maintenance?

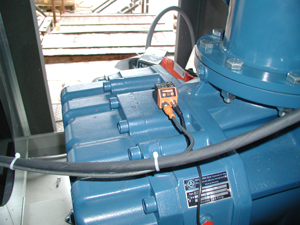

Trending is the key to success with precision maintenance. At Aerzen USA we make good use of state of the art condition monitoring devices that fit any budget. From low cost vibration sensor based switches to full blown online monitoring systems ranging from IFM Efector's VKS, Octavis and Multiplex devices we have the trending system that will fit anyone's budget.

Tags: Aerzen, positive displacement, rotating equipment, compressors, Aerzen USA, pd blower, rotary lobe blower, pneumatic conveying

There are many solutions that can help avert such issues. One effective one comes from the Lean Manufacturing program called 5S in which - among other important aspects - lets you sort and mark all items you need to do your job with. This is perfect for lubricants. Visual signals such as color coding bins, drums and cans and using the same colors on markings on the actual equipment will make anyone's life a lot easier and also help you reach the maximum service life of your equipment.

Tags: Aerzen, positive displacement, compressors, oil-free screw process gas compressor, Aerzen USA, pd blower, rotary lobe blower, oil-flooded screw compressor, pneumatic conveying, aeration

Considerations when specifying and purchasing a screw compressor

1) Type of compressor: positive displacement or dynamic

Tags: Aerzen, positive displacement, rotating equipment, compressors, screw compressor, oil-free screw process gas compressor, pd blower, rotary lobe blower, turbo blowers, sliding vane compressor, oil-flooded screw compressor

Things to consider when making blower purchasing decisions

Performance - Only buy Aerzen's blower packages... just kidding, but there is a serious point here. Any manufacturer's claims of performance need to be verified to insure the correct amount of pressure will be generated for the application. Insist on knowing the performance and efficiencies (power requirements) of the complete blower package you buy not just the performance of the bare stage. An undersized drive motor will limit performance.

Tags: Aerzen, positive displacement, rotating equipment, pd blower, rotary lobe blower, turbo blowers, pneumatic conveying

Call to action will go here below

This is the content. This is demonstration text. Click 'edit' above to create your own content.