The segment from WaterOnline Radio features interviews with John Franz, wastewater treatment plant manager for the City of Anacortes, WA, as well as Kevin Grant, a regional sales manager for Aerzen USA.

Aerzen USA insights and guidance for blower, compressor and vacuum pump applications

Aeration Blower Saves $44K Annually For Wastewater Treatment Plant

Tags: Aerzen, positive displacement, rotating equipment, Aerzen USA, pd blower, rotary lobe blower, turbo blowers, blower sizing, wastwater, water treatment, WWTP, aeration

A Turbo Blower for the Base Load, PD Blower for the Peak Load

A biological municipal wastewater treatment plant with a considerably fluctuating discharge quantity can only perform its function with utmost energy efficiency and reliability if the process air consumption of the aeration basin can be adjusted continuously and is fully automated in order to deal with widely fluctuating load quantities. The example of the wastewater treatment plant shows how this is achieved with the use of a speed controlled Aerzen turbo blower.

Tags: Aerzen, positive displacement, rotating equipment, Aerzen USA, pd blower, turbo blowers, blower sizing, wastwater, water treatment, WWTP, aeration

How To Choose The Right Blower For Wastewater Treatment (Podcast)

Three main blower technologies are condsidered for waste water treatment applications:

Tags: Aerzen, positive displacement, Aerzen USA, pd blower, rotary lobe blower, turbo blowers, blower sizing, wastwater, water treatment, WWTP, aeration

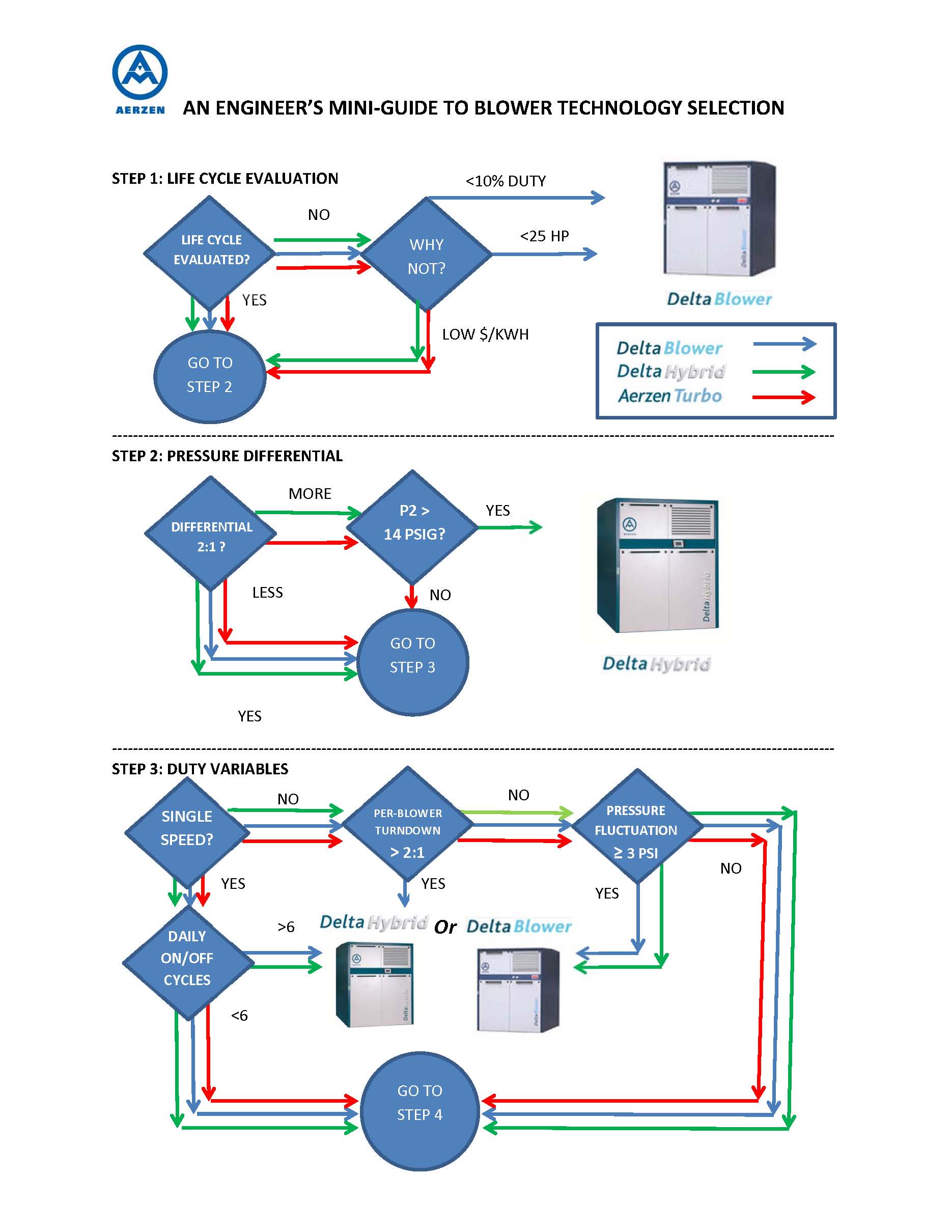

An Engineer's Mini-Guide To Blower Technology Selection

Turbo Blowers. Positive Displacement Blowers. Hybrid Rotary Lobe Blowers. Which one should you choose for your wastewater treatement application? How much energy can you really save? Who can you trust to give you an objective answer? The best place to start is by downloading the Engineer's Mini-Guide To Blower Technology Selection.

Tags: Aerzen, positive displacement, compressors, Aerzen USA, pd blower, rotary lobe blower, turbo blowers, blower sizing, wastwater, water treatment, WWTP

Real-time Condition Monitoring For Blowers And Compressors

The Aerzen iAir Remote Monitoring System (RMS) is a comprehensive monitor that can be attached to any blower or compressor to capture real-time activities and conditions. Based on industrial cellular technology, the RMS can function in any location with cellphone coverage for both indoor and outdoor applications. The system is easily installed and linked directly to your cell phone for up-to-the-minute condition reports and notifications. This allows for peace of mind and troubleshooting when you are not accessible to the equipment.

Tags: Aerzen, positive displacement, Aerzen USA, pd blower, rotary lobe blower, pneumatic conveying

Shipping damage is the top number one issue followed by scheduling and only then cost. It is amazing how much freight gets damaged per year. This is particularly true for new blower packages that are shipped via LTL (Less than truckload) and so called common carrier. Although deemed the most cost effective – expediting and broker companies managed to push the cost down - it is the most difficult way to get machinery to a job site undamaged. Because freight must be consolidated in the carrier’s main hubs the equipment must be moved often. The mostly heavy and odd shaped freight with uneven weight distribution is moved with fork trucks that are significantly undersized. Making things worse is the fact that logistics is a business model where people make Cents on a Dollar and thus the time freight spends in non value adding moving around within terminals is kept to an absolute minimum causing fork lift drivers to drive fast and furious. Freight gets shoved around, stacked (when it should not be) and dropped rapidly (giving drop-shipment a different meaning). The result is that sound enclosures, castings, instrumentation etc gets damaged significantly before it even makes it to the final destination.

Tags: Aerzen, rotating equipment, screw compressor, Aerzen USA, pd blower, rotary lobe blower, turbo blowers

Operating Time Versus Condition Based Oil Changes

The majority of all operating manuals provide the equipment user with a time based plan when to change the machine’s oil. This interval is typically designed to protect the oil and subsequently the machine from breaking down prematurely in most if not all operating conditions. So far so good. This comes with a price tag as the machine needs to be properly shut down and locked / tagged out. Besides of the obvious cost for the lubricant you also incur labor and potential production down time cost. For most of the smaller machines requiring less than a gallon of oil for each change it may not make sense to go with a condition based lubricant change. Experts fix what needs fixing and this applies here also. For larger quantities it may make much more sense to go with an oil condition based oil change schedule.

Tags: Aerzen, positive displacement, screw compressor, Aerzen USA, pd blower, turbo blowers, wastwater

Top 5 Questions To Ask When Sizing A Blower System With A Vacuum Pump

In order to properly size a blower system with a vacuum pump, there are five main requirements to consider:

Tags: Aerzen, positive displacement, rotating equipment, screw compressor, Aerzen USA, pd blower, rotary lobe blower, blower sizing

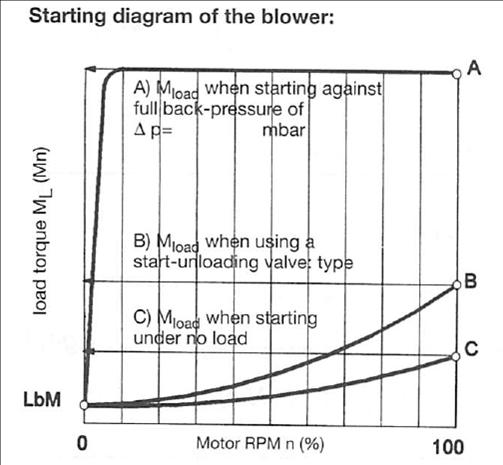

Lowering start-up power draw with across the line start - PD blower

The most common motor start is what is commonly known as “across the line” (direct) motor start. Power companies like when consumers do this as the resulting power draw (Amperage) spike is typically assessed with so called power demand charges on top of the regular power consumption charge in cents/kWh. In any application where the blower or compressor must start against header pressure this starting method carries the greatest penalty as the motor must overcome the rotating equipment’s moment of inertia and the system pressure. The graph below illustrates the power draw and the time it takes to bring the blower / compressor on line. An Aerzen Aeromat automatic start-up unloading valve may be the answer to your problem.

Tags: positive displacement, Aerzen USA, pd blower, rotary lobe blower, blower sizing

Of Pipework And Other Surprises During Blower And Compressor Start-up

Day of start-up is always an exciting time as all the long hard work of engineers and construction folks can finally show off what they have worked on for typically a long time. Most focus is placed on equipment, infrastructure, controls and plant processes. One item that is often underestimated in air and gas moving equipment is the pipe-work that connects primary air movers and the process. Materials of construction, alignment, thermal growth allowance and most of all cleanliness continue to be one of the most unique challenges start-up engineers continue to encounter.

Tags: positive displacement, rotating equipment, Aerzen USA, pd blower, rotary lobe blower, pneumatic conveying

Call to action will go here below

This is the content. This is demonstration text. Click 'edit' above to create your own content.