Since its foundation in 1868 the Probat-Werke has concentrated with more than 600 employees worldwide on roasting machines and equipment for coffee and food industry. Until today, the world market leader has sold more than 110,000 roasting machines – from manual global roaster via fully automatic largescale roasters up to the new tangential roaster Jupiter Hybrid with which the most diverse roasting profiles can be prepared in one roasting machine.

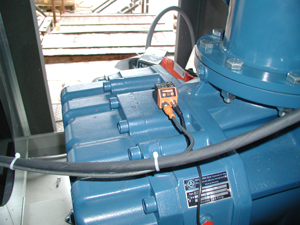

For transport of the coffee, Probat prefers the pneumatic conveyance. As the

conveying air is in direct contact with the product, it has to be absolutely oilfree. For production of the conveying air as negative pressure, Probat has used Aerzen units since 1996.

In September 2012, Probat opened a new Research and Technology Centre. There, the conveying air required in the roasting machines is generated by two Delta Blowers Generation 5 and one Delta Hybrid. Upon storage of the green coffee into silos with overpressure between 1,000 and 2,000 mbar, the Delta Blower is used, also during transport to the roasting machine with positive pressure.

The Delta Hybrid is responsible for transport of the particularly sensitively

roasted beans to the roasted coffeesilos and to bagging station with negative pressure as well as for transport to grinding plant with overpressure. The Delta Hybrid unit generates a negative pressure of 300 mbar on suction side as well as an overpressure of 600 mbar on discharge side. Therefore, a conventional blower unit could be replaced acc. to the principle “Two become

one”.

Again, two Delta Blowers transport the ground coffee to the ground coffee silos and to the packaging machines with negative pressure. As an alternative, however, the Delta Hybrids can also be used. The required differential pressure is decisive for the selection dependent on the piping length and the specific energy advantages of the Hybrid.

All Aerzen units are fully automatically integrated in the process of the roasting equipment and are switched via a superordinated intelligent SPS control depending on the program. The respective blower units are driven with a constant volume flow whereby the pressure is built up depending on conveying capacity and pipe length. Thanks to a bypass solution, Aerzen

had developed together with Probat, a part of the volume flow can be led back from discharge to suction side for the positive pressure units.

Read More

Tags:

Aerzen,

rotating equipment,

rotary lobe blower,

pneumatic conveying,

Hybrid Blower,

Coffee Conveying

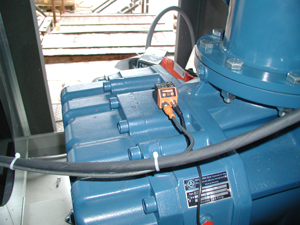

The Aerzen iAir Remote Monitoring System (RMS) is a comprehensive monitor that can be attached to any blower or compressor to capture real-time activities and conditions. Based on industrial cellular technology, the RMS can function in any location with cellphone coverage for both indoor and outdoor applications. The system is easily installed and linked directly to your cell phone for up-to-the-minute condition reports and notifications. This allows for peace of mind and troubleshooting when you are not accessible to the equipment.

Read More

Tags:

Aerzen,

positive displacement,

Aerzen USA,

pd blower,

rotary lobe blower,

pneumatic conveying

Plant air is a known energy sink and you may not think of a shop air compressor as an area that can be made more sustainable. At Aerzen’s LEED certified facility in Coatesville we initially were not able to improve upon old concepts at first either. During the course of the last three years we were able to make significant changes to reduce its environmental impact. Adding an electronic controller, variable speed drive, remote monitoring and recycling waste heat did a fantastic job reducing the carbon foot print of the compressed air system. They are simple ideas that you can implement in one way shape or form. Your bottom line may be affected by this more than you think.

Read More

Tags:

positive displacement,

rotating equipment,

compressors,

screw compressor,

oil-free screw process gas compressor,

Aerzen USA,

oil-flooded screw compressor,

pneumatic conveying

Day of start-up is always an exciting time as all the long hard work of engineers and construction folks can finally show off what they have worked on for typically a long time. Most focus is placed on equipment, infrastructure, controls and plant processes. One item that is often underestimated in air and gas moving equipment is the pipe-work that connects primary air movers and the process. Materials of construction, alignment, thermal growth allowance and most of all cleanliness continue to be one of the most unique challenges start-up engineers continue to encounter.

Read More

Tags:

positive displacement,

rotating equipment,

Aerzen USA,

pd blower,

rotary lobe blower,

pneumatic conveying

Oil analysis and vibration analysis make a great tag team when it comes to assessing rotating equipment condition. Even if oil analysis trending is carried out by itself it still can be a powerful tools assessing whether or not there may be trouble coming down the pike – rolling element bearings, gears and other key components leave key evidence of them failing behind in the lubricant. Depending on your plant size and usage of lubricant, quite a few lubricant suppliers also offer free oil analysis. While that seems great at the first glance, there are quite a few wrinkles that can lead straight to catastrophes that the analysis was supposed to help prevent. I will review a few issues and elaborate on what an analysis report should cover in the course of this blog.

Read More

Tags:

Aerzen,

positive displacement,

rotating equipment,

screw compressor,

pd blower,

rotary lobe blower,

turbo blowers,

WWTP,

pneumatic conveying

Have you ever pondered the term of "preventative" maintenance? Well, I have often done so and must admit that I had to laugh when I pictured how this was supposed to actually work in a plant setting. It conjured up visions of maintenance people getting a "call" from the machine controls in question and telling them to come in soon as one of the bearing will fail next Sunday night at 4:05am. While we are closer than ever in diagnosing machinery problems and averting the worst from happening, we are not able to be able to exactly "predicting" when the usable time of a piece of equipment will come to an end. Precision maintenance is when you identify, prioritize and implement a condition monitoring philosophy that is trending based and is designed provide a review process for any process and incident occurrence.

Trending is the key to success with precision maintenance. At Aerzen USA we make good use of state of the art condition monitoring devices that fit any budget. From low cost vibration sensor based switches to full blown online monitoring systems ranging from IFM Efector's VKS, Octavis and Multiplex devices we have the trending system that will fit anyone's budget.

Read More

Tags:

Aerzen,

positive displacement,

rotating equipment,

compressors,

Aerzen USA,

pd blower,

rotary lobe blower,

pneumatic conveying

Is it not amazing how many different lubricants there are in a industrial or even a municipal waste water treatment plant? At the outset the problem is not all that challenging. Lubrication or maintenance managers usually start by compiling a complete list of machines and the lubricants they need as per their respective operation manuals. So far, so good. Than it starts to get complicated, because maintenance techs, operations people or lubrication crews need to do the actual work and more often than we realize they need to make their own mental notes to remind themselves which machines takes what lubricant. Sometimes people use permanent markers or other devices and leave themselves scribble notes directly on the machines themselves. How many times has that caused any machinery trouble at your plant?

There are many solutions that can help avert such issues. One effective one comes from the Lean Manufacturing program called 5S in which - among other important aspects - lets you sort and mark all items you need to do your job with. This is perfect for lubricants. Visual signals such as color coding bins, drums and cans and using the same colors on markings on the actual equipment will make anyone's life a lot easier and also help you reach the maximum service life of your equipment.

Read More

Tags:

Aerzen,

positive displacement,

compressors,

oil-free screw process gas compressor,

Aerzen USA,

pd blower,

rotary lobe blower,

oil-flooded screw compressor,

pneumatic conveying,

aeration

Sizing - Proper sizing of the blower begins when the buyer provides performance requirements to a blower manufacturer. The buyer should understand the differences between scfm (volumes at standard conditions) and icfm/acfm (volumes at intake or actual conditions). Knowing the ambient conditions (elevations and temperature ranges) and the required operating pressures which the blower must produce will also effect the manufacturer's selection.

Performance - Only buy Aerzen's blower packages... just kidding, but there is a serious point here. Any manufacturer's claims of performance need to be verified to insure the correct amount of pressure will be generated for the application. Insist on knowing the performance and efficiencies (power requirements) of the complete blower package you buy not just the performance of the bare stage. An undersized drive motor will limit performance.

Read More

Tags:

Aerzen,

positive displacement,

rotating equipment,

pd blower,

rotary lobe blower,

turbo blowers,

pneumatic conveying

Are you ready to buy a blower for a pneumatic conveying system? Look out for the following:

Feel free to comment or contact me to discuss.

Karl Mueller - Industrial Specialist

Aerzen USA

(770) 951-7035

kmueller@aerzenusa.com

Read More

Tags:

Aerzen,

positive displacement,

rotating equipment,

rotary lobe blower,

blower sizing,

pneumatic conveying